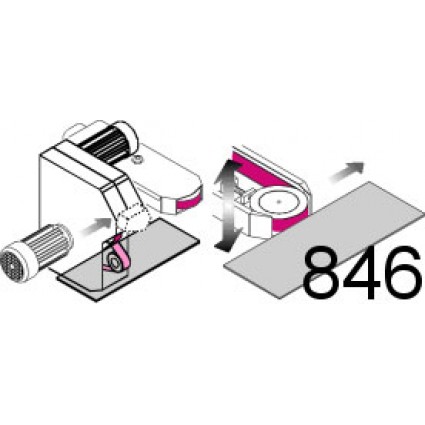

EUROFINTEC 846

The machine was created for deburring edges on linear cut

pieces of shears, punching machines with micro junctions, plasma, lasers, and

performs the two chamfers on both sides of the piece in one pass, ensuring a

significant reduction in processing times. It consists of a cabinet base, which

can hold spare abrasive belts and any accessories and is equipped with four

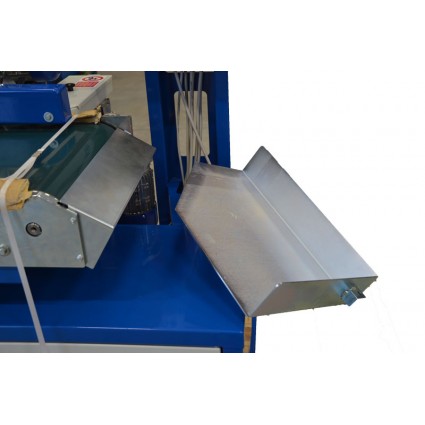

swivel wheels, two of which with brakes. Variable speed conveyor belt unit,

which can be tilted up to 30 ° to facilitate the insertion and alignment of the

pieces during automatic processing. The speed of the conveyor belt can be read

on a display directly in meters / minute and can be varied by acting on the

appropriate potentiometer

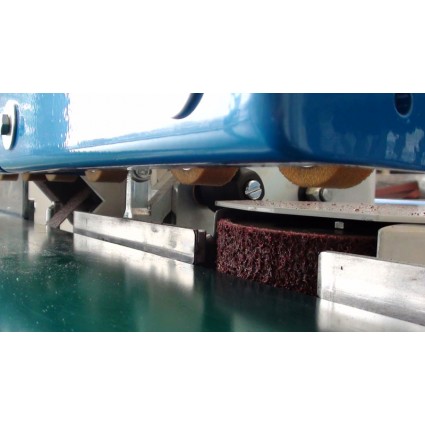

The 846 model is composed of a fixed chamfering head

equipped with two crossed free belts for chamfering from 0.1 to 1 mm on any

type of material with thicknesses from 0.2 to 30 mm and a second horizontal

head with belt on contact wheel, oscillating to ensure longer life of the belt,

which also allows processing of polishing and satin finishing of the edge.

Equipped with self-filtering suction system for collecting dust directly from the processing point.

|

Abrasive belt speed |

m / sec 24 |

|

Conveyor belt size |

1100 x 400 mm |

|

Conveyor belt speed |

m / min from 6 to 30 |

|

Development of abrasive belt head 846 |

900 x 25 mm |

|

Air intake volume |

m³ / h 700 |

|

Maximum footprint |

800 x 600 x 1480 mm |

|

Indicative weight |

295 kg |